Posted by Zosi Learning

Imagine becoming the expert everyone turns to when food safety questions arise. Mastering how to write a HACCP plan positions you as a crucial resource within your organization, boosting your credibility and professional value. With increasing attention on foodborne illnesses, strong HACCP knowledge ensures you not only protect consumers but enhance your brand’s reputation.

Every food safety recall in the news acts as a powerful reminder of why having a robust HACCP food safety plan is essential. Proactively implementing or reviewing your HACCP practices during these moments ensures you stay ahead of potential risks, safeguarding your organization and public health.

Understanding the Importance of HACCP

At its core, a HACCP plan is about more than compliance—it’s about protecting lives. Each year, millions are impacted by foodborne illnesses, underscoring your role in creating thorough and effective food safety procedures. Developing your HACCP plan thoughtfully demonstrates your genuine commitment to consumer safety, building lasting trust and confidence.

Transparency in your food safety practices is crucial. Making your HACCP processes visible and accessible—through examples posted in your facilities or online—reassures customers about your commitment to rigorous standards, setting you apart from competitors.

What Exactly is HACCP?

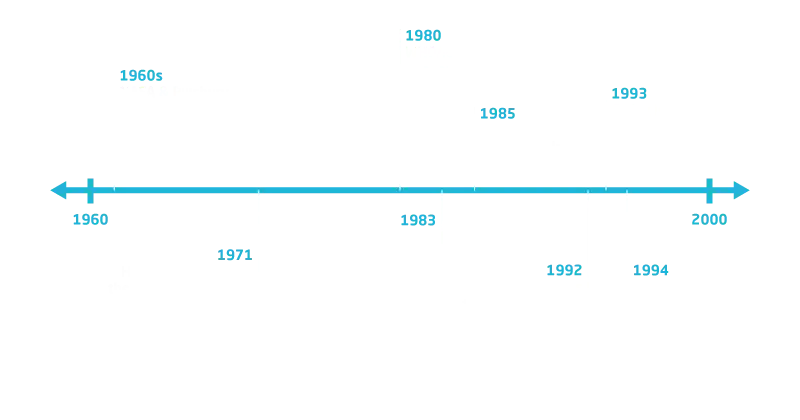

Hazard Analysis Critical Control Point (HACCP) is a systematic approach designed to ensure food safety by identifying, evaluating, and controlling hazards significant to food safety. Originating in the 1960s to ensure safe food for astronauts, HACCP is now recognized globally as the standard method for food safety management.

The seven principles of HACCP provide a solid foundation for developing a plan tailored to any food production or handling process. Organizations that successfully implement HACCP often see improved product consistency, reduced risk of recalls, and higher customer confidence.

Step-by-Step Guide to Creating Your HACCP Plan

Creating your HACCP plan doesn’t have to be complicated. Here’s a clear overview to help you get started:

- Form Your HACCP Team: Assemble knowledgeable individuals familiar with your processes. Include quality assurance, operations, and technical staff.

- Define Your Product: Clearly detail ingredients, processing methods, packaging, and shelf-life. Accuracy is critical here.

- Outline Intended Use: Specify how your products are consumed, noting vulnerable groups such as children and elderly populations.

- Construct and Verify a Flow Chart: Map production steps from receiving raw materials to distributing the final product, verifying each step onsite.

- Conduct Hazard Analysis: Identify potential biological, chemical, and physical hazards that could affect food safety.

- Establish Critical Control Points (CCPs): Pinpoint steps where control measures are necessary to prevent, eliminate, or reduce hazards.

- Set Critical Limits: Define precise thresholds for each CCP—these might include temperature limits, time constraints, or pH levels.

- Develop Monitoring Procedures: Implement procedures to consistently track CCPs, ensuring they’re within established limits.

- Define Corrective Actions: Outline clear responses for any deviations observed during monitoring.

- Implement Verification Procedures: Regularly check that your HACCP plan is effective through auditing and testing.

- Maintain Accurate Records: Document all steps, from hazard analysis and CCP identification to corrective actions and verifications.

It’s important to remember that each of these steps needs to be adapted to your specific facility. A HACCP plan for a dairy processor will look very different than one created for a frozen vegetable packer. The steps are universal, but the application is highly contextual.

Common Pitfalls to Avoid:

- Neglecting regular staff training and retraining.

- Failing to clearly document procedures.

- Insufficiently monitoring CCPs.

- Overlooking verification and validation steps.

- Applying a “one size fits all” plan to unique products or processes.

Visual Tools and Resources

Visual tools enhance understanding and execution of a HACCP plan. Incorporate flowcharts, decision trees, CCP monitoring logs, and record-keeping templates to streamline your HACCP processes.

Consider hosting these visuals in a central internal dashboard, where QA and operations teams can collaborate and stay aligned. Additionally, periodic internal audits using these tools can help keep the system up to date.

Industry-Specific Examples

Beyond bakeries, consider the following scenarios:

- Dairy Processing: CCPs could include pasteurization temperatures and storage conditions.

- Seafood Facilities: Critical limits might involve cooling temperatures and handling of raw versus cooked products.

- Meat Processing: CCPs often focus on cooking and chilling processes to prevent contamination.

- Fresh Produce: Potential hazards may come from irrigation water, pesticide use, and cross-contamination during washing or packing.

- Ready-to-Eat Meals: Requires close attention to reheating, packaging, and time/temperature control for safety.

Each of these industries faces unique regulatory oversight and food safety risks, which means the example HACCP plan used should always be adapted accordingly.

Real-Life Impact

“I recently attended the HACCP training, and I must say it was exceptional. The content was comprehensive and very well-organized, making complex topics easy to understand. The instructor was knowledgeable and engaging, which greatly enhanced the learning experience. I highly recommend this training to anyone looking to deepen their understanding of HACCP principles.” – Donald Munro, RAIN Bottling Company

Food safety is more than compliance. It’s about cultivating a proactive culture of continuous improvement. Formal HACCP training not only sharpens your skills but also helps elevate your credibility as a safety leader.

Zosi’s HACCP certification programs are built by industry experts to combine regulatory knowledge with practical, day-to-day applications. Whether you are refreshing a legacy plan or developing one from the ground up, ongoing education is essential.

Regular reviews and retraining help identify gaps, keep your team aligned, and reduce the risk of foodborne illness. A well-trained team is your strongest line of defense.

To maintain effectiveness, review your HACCP plan at least annually—or whenever a process or product changes. This could include switching suppliers, updating equipment, or launching a new product line. A stagnant HACCP plan invites gaps in food safety.

Continuous Improvement & Training

Zosi Learning provides course modules developed by industry experts, practical examples, and self-paced online training designed to keep your knowledge current and applicable. Our programs are designed to meet regulatory requirements while being practical for day-to-day operations.

Get Started Now

Ready to elevate your food safety strategy? Enroll in Zosi’s Basic HACCP Certification Course today and confidently lead your team toward safer, compliant food production.

Whether you’re starting from scratch or refining a legacy plan, this guide is your foundation. The right training, tools, and mindset will help you turn HACCP from a regulatory task into a core pillar of operational excellence.

Basic HACCP Certification Course

Basic HACCP Certification Course

Advanced HACCP Certification Course

Advanced HACCP Certification Course